Energy efficiency

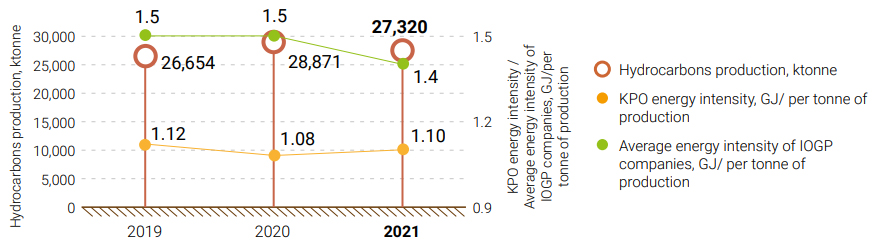

As part of the energy efficiency activities, KPO conducts energy analysis and energy efficiency monitoring. Based on the analysis results, KPO energy intensity has been relatively stable in the period of 2014–2020 with 1-2 % variation. In 2021, there was an increase in KPO energy intensity by 6.5 % compared to 2014, which is associated with a decrease in hydrocarbon production due to limited gas supplies to the Orenburg Gas Processing plant and shutdowns at Unit 2.

The benchmarking has shown that KPO’s energy intensity is below the average indicator of the companies reporting to IOGP. The results of this analysis have shaped the basis for defining our energy policy, goals and objectives, and measures for energy saving and efficiency improvement of the Company.

In order to minimize energy efficiency risks and impact of the Company, we have set a number of targets. The results of their implementation are presented further in the text.

Why is it important to us?

To ensure production of hydrocarbons while making the transition to low-carbon technologies is one of the challenges faced by KPO.

Our targets include implementation of energy efficiency measures and their evaluation, covering best available technologies, energy-saving equipment, and eco-friendly materials.

|

Our 2021 targets |

Target achievement |

Actions taken in 2021 |

Targets for 2022 |

|

Complete the energy audit and develop a five-year energy saving and energy efficiency improvement action plan |

Partially completed |

Energy audit completed. A draft five-year energy saving and energy efficiency improvement action plan has been prepared. |

Conduct an annual energy analysis of the Company and continue monitoring energy efficiency indicators for equipment/processes that have a material impact on KPO’s energy intensity |

|

Conduct a surveillance audit of the Energy Management System for compliance with the ISO 50001:2018 standard |

Completed |

A surveillance audit of the Energy Management System against the ISO 50001:2018 standard was successfully conducted in August 2021. |

Conduct a surveillance audit of the Energy Management System against the ISO 50001:2018 standard |

ENERGY MANAGEMENT SYSTEM

The ISO certification contributes to enhancement of the KPO reputation as a reliable partner to the Republic of Qazaqstan that takes appropriate actions to meet both regulatory requirements and international standards.

In August 2021, KPO has successfully conducted a certification audit against the ISO 50001:2018 standard. Following the audit, the KPO Energy Management System was recognized as corresponding to the international standards.

Energy consumption

In accordance with the energy saving and energy efficiency legislation requirements, KPO conducts a mandatory energy audit every five years.

The targets of an energy audit is to assess the Company’s efficiency in using fuel and energy resources and to develop measures ensuring rational energy consumption and increasing energy efficiency.

In 2021, a mandatory energy audit was completed at KPO by a specialized company in line with which, the overall KPO’s energy saving and energy efficiency activities were rated as 'excellent'. Also, energy efficiency improvement measures were proposed, featuring economic feasibility and practical application. One of the measures was the installation of a waste heat boiler at the gas turbine power plant is scheduled to include in the Energy Saving and Energy Efficiency Action Plan for 2022–2025.

In 2021, the energy consumption totalled 1,029,538 tonnes of coal equivalent compared to 1,067,135 tonnes of coal equivalent in 2020. The decrease in energy consumption is related to the repair works on gas turbine generators. Table 36 shows energy consumption volumes broken down by energy type.

Tab. 36. KPO energy consumption in 2019 – 2021

|

Type of energy |

Unit of meas. |

Energy consumption, physical units |

Energy consumption, tonnes of coal equivalent |

Energy consumption, GJ |

||||||

|

2021 |

2020 |

2019 |

2021 |

2020 |

2019 |

2021 |

2020 |

2019 |

||

|

Fuel gas |

Thous.m3 |

832,863 |

863,029 |

826,806 |

1,026,088 |

1,063,251 |

1,018,625 |

30,074,639 |

31,163,893 |

29,855,886 |

|

Electric power (purchased) |

MW/h |

6,710 |

6,236 |

7,244 |

825 |

767 |

891 |

24,181 |

22,482 |

26,115 |

|

Diesel fuel |

m3 |

705 |

1,188 |

739 |

888 |

1,498 |

932 |

26,027 |

43,905 |

27,468 |

|

Gasoline |

m3 |

228 |

199 |

226 |

251 |

220 |

249 |

7,357 |

6,439 |

7,301 |

|

Heating (in rented offices) |

Gcal |

10,388 |

9,781 |

8,731 |

1,486 |

1,399 |

1,249 |

43,555 |

40,994 |

36,595 |

|

TOTAL |

|

|

|

|

1,029,538 |

1,067,135 |

1,021,946 |

30,175,759 |

31,277,713 |

29,953,365 |

In 2021, the energy intensity indicator was 1.10 GJ /tonnes of hydrocarbons, which was below the average energy intensity indicator of the companies that submitted their reports to the IOGP9 (1.4).

Graph 22. Dynamics of energy intensity, 2019 – 2021

Energy saving activities

Pursuant to the approved Energy Saving and Energy Efficiency Improvement Action Plan, KPO took the following actions in 2021:

- The activities on replacement of traditional lamps with LEDs bulbs at production and ancillary facilities were continued. In 2021, 4,917 lamps were replaced at the Company`s facilities. Estimated economy of energy consumption from the traditional lamps replacement was about 754,600 KW/h. In the period of 2019 – 2021, 10,385 lamps were replaced and around 1,271,230 KW/h saved.

- Enhancement of fuel gas accounting continued including:

- installation of an ultrasonic flow meter at KPC section 5-340 – planned for III quarter of 2022;

- installation of the metering device on the gas turbine of the re-injection compressors.

- Training sessions were held for Production Department’s employees on the energy management system ISO 50001:2018.