The main objective of Asset Integrity is to prevent major accidents and reduce the risks to people, environment, assets, and the Company’s reputation. It is an outcome of good design, construction, operating and maintenance practice.

Asset Integrity is achieved when facilities are structurally and mechanically sound and perform the processes to produce the products for which they were designed. Barriers that relate to the plants, people and processes are defined to reduce the risk for a major accident to a level that is as low as reasonably practicable.

Asset Integrity and critical incident management

Asset Integrity

KPO monitors potential threats to its operations and mitigates Asset Integrity risks through its barrier management system. The Asset Integrity department together with the Units continuously assess the health status of the safety barriers to identify weaknesses, implement mitigating measures and establish plans to re-instate these barriers to its original design to prevent any major accident.

In order to minimize asset integrity risks, we have set a number of targets. The results of their implementation are presented further in the table.

Tab. 4. Targets in Asset Integrity

|

2022 targets |

Target achievement |

Actions taken in 2022 |

Targets for 2023 |

|

Further implement the Barrier Model (BM) tool, increase understanding and ownership of this tool by the Units. Further develop enhanced functionality of the BM tool. |

Ongoing

Ongoing |

|

|

|

Review the effectiveness of the implementation of the Process Safety Fundamentals (PSF) |

Ongoing |

|

|

The Asset Integrity Management Framework is a set of processes to prevent major accident hazards and to raise Asset Integrity and Process Safety awareness amongst the KPO employees, contractors and subcontractors working at the Karachaganak field.

The Asset Integrity Framework Management System consists of the following key processes:

- Barrier Management – through the application of a structured process supported by the using of the Barrier Model tool;

- Asset Integrity Performance Analysis – through the use of Key Performance Indicators;

- Management of Change system for Brownfield Modifications – through the use of the Management of Change database;

- Asset Integrity Assurance – through the use of reviews, audits, verifications and assessments;

- Asset Integrity Improvement Culture initiatives – through the production of e-Learning modules on the Mechanical Isolation Procedure, Process Safety Fundamentals and the Barrier Model process.

Within 2022, KPO has undertaken a number of activities addressing the key risks or barriers in the KPO asset integrity. In the table below, we present the completed activities in 2022 and the current status of the ongoing ones.

The activity currently ongoing will allow reducing the Process Containment and Ignition control risks field wide.

Tab. 5. Activities addressing the key risks or barriers in the KPO asset integrity

|

Barrier Impacted – finding and site place |

Continuous Improvement Activities in Asset Integrity |

|

ACTIVITIES COMPLETED IN 2022 |

|

|

Process Containment – Undersized pressure safety valve field wide |

A Safety review done by Engineering department highlighted potential undersized PSV’s in the facilities. The undersized PSV’s replaced during turnaround – 2022 at KPC, Unit-2. |

|

Process Containment – Valves with banned materials field wide |

During turnaround –2022 valves were replaced within KPC, Unit-2 and Gathering |

|

Soft Barrier – Safety Critical Elements (SCE) at Gathering / Unit 3/ Eco-Centre |

4th ICP at Unit-2 has been completed and as part of the Handover to the Operations, the identification of the relevant SCE of the 4ICP project has been carried out. |

|

Soft Barrier –compliance assessment on Temporary Management of Change (MoC) process effectiveness |

In order to verify compliance with the KPO procedures, an assessment was carried out on Temporary MoC process effectiveness |

|

ACTIVITIES STARTED IN 2022 ONGOING THROUGH 2023 |

|

|

Protection Systems – Caustic Neutralisation Unit Shutdown system |

Construction started in 2022 and tie-ins for new UOP Thermal Oxidation within TA-2022 done, New Caustic Neutralisation Unit to be installed in 2023 |

|

Ignition Control – EX Equipment field wide |

Site inspections completed, most critical items repaired/replaced, remaining scope being addressed. |

Barrier model

In 2022, the KPO Asset Integrity Department has worked on the enhancement of the Barrier Model software tool and integration with other software applications.

Spills

In 2022, no cases of significant spill1 were recorded at the territory of the Karachaganak field.

1 The definition of a significant spill is applied to an incident, which has caused contamination of the environment through hydrocarbon/chemical spills to land or water and volume of spilled hydrocarbon/chemical exceeding 1,000 litres (as per KPO Incident classification).

Loss of primary containment

Loss of Primary Containment (LOPC) is an unplanned or uncontrolled release of any material from primary containment, including non-toxic and non-flammable materials. The Annual Loss of Primary Containment Report for 2022 provides an analysis of the LOPC incidents that occurred during 2022 along with their defined recovery actions in terms of:

- Root causes (in accordance with Incident Investigation Tap Root Methodology),

- Level of compliance with Process Safety Fundamental rules,

- Status of corrective actions,

- Weeps & Seeps Leaks Register data.

Analysis of Process Safety Events (LoPC) is the key to prevent or reduce the likelihood and severity of Process Safety Events. Once a Process Safety event occurs, an investigation process is initiated, root causes are determined and recommendations are defined and followed up through the Synergi database.

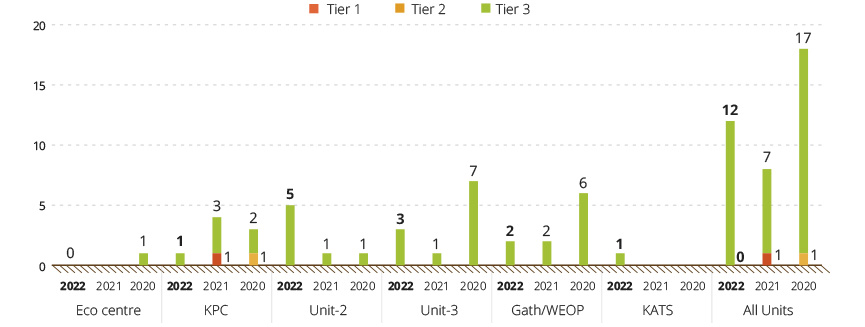

2022 is the first year in KPO history with no Tier-1 and Tier-2 LOPC events (application of the IOGP terminology in KPO started in 2014). The number of Tier 3 LOPCs in 2022 was 12.

Graph 2. Loss of Primary Containment at KPO by process facilities, 2020–2022

Emergency response and crisis management are the key processes of the KPO management system since, if an emergency situation escalates, KPO and contractors’ personnel, as well as the neighbouring communities, may happen to be within the possible hazard impact area.

Emergency preparedness and response implies a recognition of possible irregularities and accidents, as well as creation of an organizational structure and resources for the mitigation of such accidents’ effects on people, the environment, the Company’s assets and reputation. These resources are also used to render support to the Burlin District state emergency and rescue capabilities in fighting fires on residential and agricultural lands, as well as in combating floods.

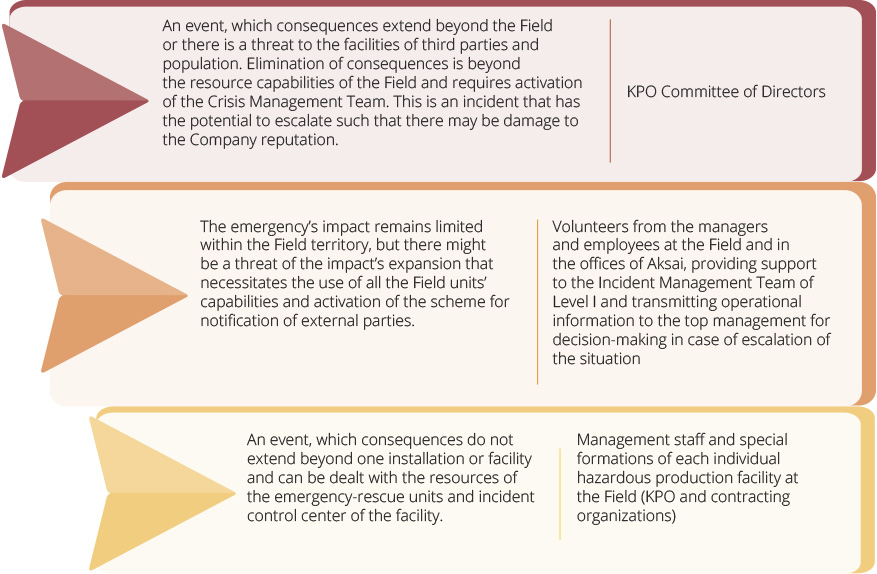

Critical incident management

In case of any incident, accident or emergency, KPO operates a robust three-level Emergency Response system used to trigger a prompt response, assessment of emergency scale, planning and implementation of actions to localize and eliminate emergency and its consequences. The system is graphically shown on figure 5.

In 2022, KPO continued training of Incident Management Team in accordance with the approved schedule.

Weekly, theoretical and practical trainings were carried out throughout 2022 with the involvement of KPO Civil Protection Units, namely:

- firefighting teams;

- gas rescue team;

- voluntary emergency-rescue team;

- medical units.

Fig. 5. KPO emergency response system

Totally, 48 drills have been conducted with the involvement of KPO Civil Protection Units at the training area.

Moreover, in 2022, KPO continued training of staff in civil protection via the e-learning system, as required by the RoQ legislation.

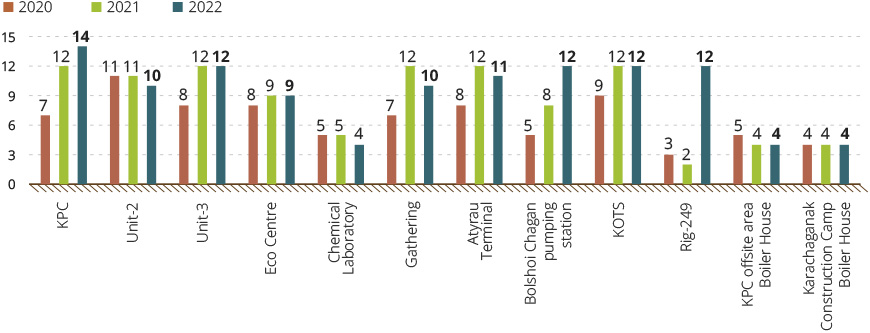

In 2022, as part of ensuring the readiness of level I forces and resources, all Company’s hazardous production facilities conducted monthly emergency response drills with the involvement of the Facility Incident Command Team (ICT), emergency rescue teams and KPO and contractors’ personnel.

The total number of emergency response drills conducted in 2022 at KPO facilities for the purpose of exercising the actions of level I incident command teams and emergency rescue units amounted to 114 drills (103 in 2021).

Also, in accordance with the requirements of Order of the Minister of the RoQ Emergency Response #349 dated 16.07.2021 “On approval of guidelines to develop Emergency Response Plan and conduct emergency response drills at hazardous production facilities” 12 emergency training exercises were conducted of which 5 emergency training exercises were carried out with involvement of the II FIMC level.

Besides, KPO continues its active engagement with local authorities in the periods of high water, fire hazard and winter.

Throughout 2022, representatives of KPO emergency rescue teams and units responded to 12 calls by going out to settlement to provide assistance in extinguishing steppe fires at agricultural facilities, household outbuildings, and forest belt fires.

In 2022, real situations took place calling for involvement of KPO emergency management system. Thus, in January 2022, due to social tension and events in the country and region, day-and-night duty of level II EMT and level III CMT members was introduced on the basis of the Czech Camp's EMC maintaining continued readiness and response to the current operational situation.

Graph 3. Emergency response drills completed in 2020 – 2022

The level II and III centres’ members took part in the following real mobilizations and drills, which allowed maintaining the readiness level:

Tab. 6. Level II and III drills conducted in 2022

|

Type of drill |

Date |

Objectives |

Participants |

|

Table Top exercise |

2 September 2022 |

“Actions of teams and resources for eliminating oil spill at the intersection of Ural River with KATS pipeline”. The drill on recovery and elimination of emergency oil spills on water was performed for firefighting team, Incident Command Centre of PS Bolshoi Chagan and WQO Emergency Department. |

ERS and KPO units together with WQO Emergency Department |

|

Integrated exercises |

10 June 2022 |

“Actions taken by emergency management, teams and resources of emergency rescue services and KPO units during elimination of major emergencies at the Karachaganak Field Facilities”. Integrated Exercise Program for 2022 envisaged drilling of various scenarios for emergency elimination at the pre-defined 6 training areas including residential area Priuralnoe. |

Teams and resources of emergency rescue services and KPO units together with WQO Emergency Department and Burlin district Akimat |

|

Table Top Exercise BERRY |

1 December 2022 |

“Rupture or damage of 6” Unit-3 condensate pipeline”. The exercise to drill the process of warning and informing of the Operators, State and Regulatory Authorities, mass media and relatives of the injured persons was drilled. |

Personnel of Centres of the I, II, III KPO ER levels, the PARIS team |

Community preparedness

KPO maintains awareness of the community on the procedure for responding in case of emergency situation at the Karachaganak Field and along the export pipeline KATS and general fire safety requirements during fire hazard period.

In 2022, following the approved plan, 20 meetings were held for 160 people with rural districts Akims and community located around the Field to discuss such issues as: importance of the central monitoring station, village alarm stations and their intent, abidance by fire safety regulations during farming operations in fire hazard period.

21 meetings were held for 151 people from settlements located along the export pipeline KATS in the Terektinsky, Baytereksky and Akzhaiksky regions of WQO.

Practical drills were carried out to exercise joint actions of the rural districts Akimats and responsible persons when managing evacuation of the community in case of danger from the field area, interaction with ECC Dispatcher, use of village alarm stations and gas alarm system in case of threat within the settlements.

To maintain constant readiness of village alarm stations, throughout 2022, the Community Protection Specialist of KPO Emergency Response Team jointly with contractor representatives carried out monthly testing of emergency alarm signals and public address systems, as well as the maintenance of this equipment. Such village alarm stations are installed in seven villages that are situated around the field.