HEALTH, SAFETY AND THE ENVIRONMENT

PEOPLE

COMMUNITIES

Health, safety and asset integrity are the key elements for successful development and operation of any oil and gas condensate field. Safety of personnel in operations related to risks of H2S, potential leaks and road incidents is of paramount importance for our Company. Our goals are that every employee is to come back home safe and sound and production leaks are entirely excluded.

KPO utterly commits to support effective HSE culture both internally and externally.

HEALTH, SAFETY

We have a systematic approach to health, safety, security management in order to achieve continuous performance improvement.

To this end, we manage these matters as critical business activities, set standards and targets for improvement, and measure, appraise and report performance externally.

SAFETY PRACTICES

In order to minimize safety risks and impact of the Company, we have set a number of targets. The results of their implementation are presented further in the table.

Tab. 7. Our targets in safety

|

Our targets in 2022 |

Status |

Actions taken to implement targets in 2022 |

Targets for 2023 |

|

Continue implementation of the Safety Leadership Improvement Journey |

Superseded |

Safety Leadership Improvement Journey was superseded by KPO Safety Culture Transformation Plan. |

Implement Safety Culture and Leadership Transformation Plan |

|

Implement HSE Communication Plan for 2022 |

Completed |

Initiatives and campaigns included in the 2022 HSE Communications plan were implemented. |

Implement HSE Communications plan for 2023 |

|

Pass certification on ISO 39001: Road Traffic Safety Management System |

Completed |

To pass certification on ISO 39001 Standard in 2022, KPO implemented the following activities: in 2020, KPO conducted gap analysis and started preparation for the certification and in 2021, KPO successfully passed pre-certification audit on the Standard. |

Successfully pass surveillance audit on the Standard |

|

Conduct assessments to understand the level of HSE Culture in KPO |

Completed |

Number of assessments were done to identify the level of HSE Culture in KPO: 2 KPO internal assessment by peers (in March and December) and assessments by third parties and Operators (in July-August 2022). Outcome of the KPO HSE Culture level assessment: 80 % Calculative. |

Improve safety culture in KPO with focus on leadership and behavioral aspects as a part of the target to implement Safety Culture and Leadership Transformation Plan |

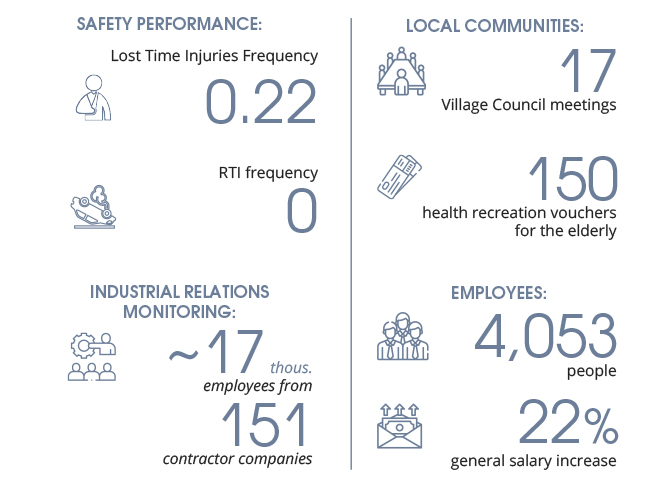

Health and safety performance

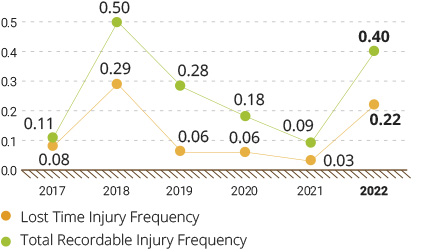

We plan our health and safety activities by tracking our progress and monitoring the world events. We calculate frequency of incidents over a set amount of work in man-hours. Our health and safety records are presented for the period 2017 – 2022 with a focus on 2022.

Graph 4 demonstrates Lost Time Injuries Frequency (LTIF)2 and Total Recordable Injury Frequency (TRIF)3.

Note: KPO uses the following method to calculate LTI and TRI frequencies:

2 Frequency of Lost Time Injuries (LTIF) = number of Lost Time Injuries (lost work day cases + fatalities) x 1,000,000 / man-hours.

3 Frequency of Total Recordable Injuries (TRIF) = number of recordable incidents (lost work day cases + medical treatment cases + restricted work day cases) x 1,000,000 / man-hours).

Graph 4. LTI and TRI frequencies: KPO and contractors, 2017–2022

In 2022, the total number of recordable injuries in KPO increased significantly from three in 2021 to 13 in 2022. The number of Lost Time Injuries also increased from one in 2021 to seven injuries in 2022. In 2022, LTIF was 0.22 (vs 0.03 in 2021) and TRIF – 0.40 (vs 0.09 in 2021). The main reason for incidents number increase is post-pandemic effect, work-scope increasing (including projects delivery), underestimation of risks level and lack of adequate focus on safety.

We investigate all incidents to avoid reoccurrence. In addition, we share learnings from incidents with our contractors and other interested parties and adopt safety improvement practices from other companies.

Table 8 represents KPO LTIF versus contractors LTIF for the last three years. KPO and contractors’ data are presented separately. To obtain a consolidated indicator, a calculation formula should be applied, and not just a summarized data used.

Tab. 8. Lost Time Injuries frequency: KPO vs contractors, 2020 – 2022

|

Performance Indicators |

2022 |

2021 |

2020 |

|

Lost Time Injury Frequency (KPO) |

0.00 |

0.14 |

0.00 |

|

Lost Time Injury Frequency (contractors) |

0.27 |

0.00 |

0.07 |

Table 9 represents KPO TRIF versus contractors’ TRIF.

Tab. 9. Total Recordable Injury Frequency: KPO vs contractors, 2020 – 2022

|

Indicators |

2022 |

2021 |

2020 |

|

Total Recordable Injury Frequency (KPO) |

0.00 |

0.14 |

0.00 |

|

Total Recordable Injury Frequency (contractors) |

0.50 |

0.08 |

0.22 |

KPO strives to make work places safe. Despite this, during 2022 there were 13 incidents, resulting in various injuries of contractors’ employees.

Tab. 10. Incidents in 2022

|

Injury Type |

Description |

Number |

|

Lost Work Day Cases |

Knee injury as a result of slipping and falling |

1 |

|

Back and head injury as a result of falling from height |

1 |

|

|

Leg injury by fallen object (spool) |

1 |

|

|

Back injury as a result of falling from height |

1 |

|

|

Back, chest and head injury as a result of falling from manlift |

2 |

|

|

Eye injury as a result of foreign body strike |

1 |

|

|

Total Recordable Injuries, where employee returned to work after medical treatment or was transferred to restricted work |

Inner lower leg injury as a result of falling through the grating |

1 |

|

Forearm injury (cut) on rebar |

1 |

|

|

Finger injury as a result of pinching |

4 |

|

|

TOTAL |

13 |

|

No severe Road Traffic Incident (RTI) was reported in 2022. The RTI frequency4 per 1 million km driven in KPO and contractors remained zero in 2022 the same as in 2020 – 2021, three years in a row. The zero rate is associated with the implementation of Road Safety Improvement Plan and other achievements as described in the Road Safety section. In 2022, the kilometers driven by KPO vehicles amounted to 39.3 million km, compared to 40.2 million km in 2021.

Fatality Frequency5 in KPO and our contractors in 2019 – 2022 remains zero.

4 KPO RTIF calculation method: RTIF = number of RTI (severe) x 1,000,000 / km driven

5 Fatality frequency calculation method used by KPO: fatality frequency (per million man-hours worked) = number of fatalities x 1,000,000 / man-hours worked.

In 2022, KPO and сontractors’ employees worked 32,515,598 man-hours: 20 % of them (6,629,709 man-hours) worked by KPO employees and 80 % (25,885,889 man-hours) by сontractors’ employees.

Tab. 11. Man-hours worked: KPO vs contractors, 2020 – 2022

|

Indicators |

2022 |

2021 |

2020 |

|

Man-hours worked (KPO) |

6,629,709 |

6,924,081 |

7,269,825 |

|

Man-hours worked (Contractors) |

25,885,889 |

25,340,974 |

26,955,757 |

|

Total |

32,515,598 |

32,265,055 |

34,225,582 |

In 2022, seven high potential incidents (HPI)6 were recorded in KPO: three incidents resulted in four lost work day cases, three asset damage cases and one near miss.

Tab. 12. High Potential Incidents: KPO vs contractors, 2020 – 2022

|

Indicators |

2022 |

2021 |

2020 |

|

High Potential Incidents (KPO) |

0 |

0 |

1 |

|

High Potential Incidents (Contractors) |

7 |

1 |

1 |

|

Total |

7 |

1 |

2 |

6 High Potential Incident (HPI) – any unplanned or uncontrolled event or chain of events that could have resulted in injuries to be accounted.

In 2022, 82 near misses (NM)7 were registered in the Company: of which 49

(60 %) were reported through the Incident Notification Procedure, and 33 (40 %) –

through HSE cards. For each near miss same as for each incident, KPO performs a thorough

investigation, identifies the causes and develops recommendations to correct the shortcomings

and prevent their recurrence.

Tab. 13. Near misses: KPO vs contractors, 2020 – 2022

|

Indicators |

2022 |

2021 |

2020 |

|

Near misses (KPO) |

24 |

22 |

27 |

|

Near misses (Contractors) |

58 |

43 |

46 |

|

Total |

82 |

65 |

73 |

7 Near-miss – any unplanned or uncontrolled event or chain of events that could have resulted in injuries to be accounted for, asset damage, the environment, or an incident related to process safety, but such consequences, by coincidence, were avoided.

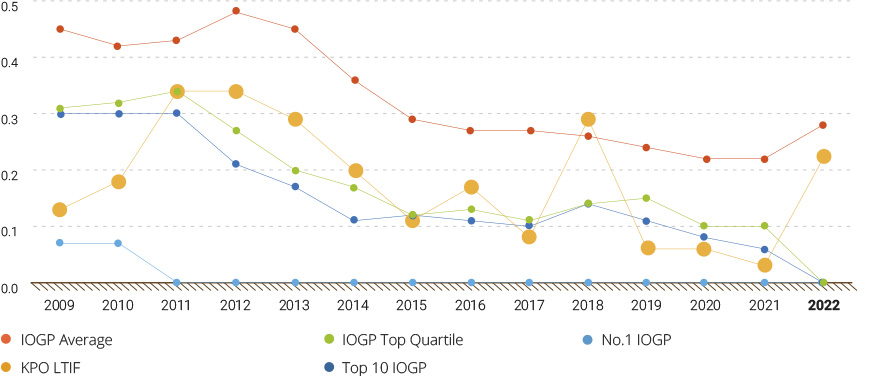

Peer comparison

Every year we review our key safety performance indicators against the other O&G producers’ indicators reported by International Organisation of Oil and Gas Producers (IOGP). IOGP annually publishes HSE performance indicators on the website www.iogp.org.

In 2022, the number of Lost Time Injuries in KPO increased (7 LTIs in 2022 versus 1 LTI in 2021). If compared with other peer companies in 2022, KPO LTIF is behind the performance of IOGP 10 top and on par IOGP average (see graph 5).

Graph 5. KPO Performance versus IOGP, 2009 – 2022

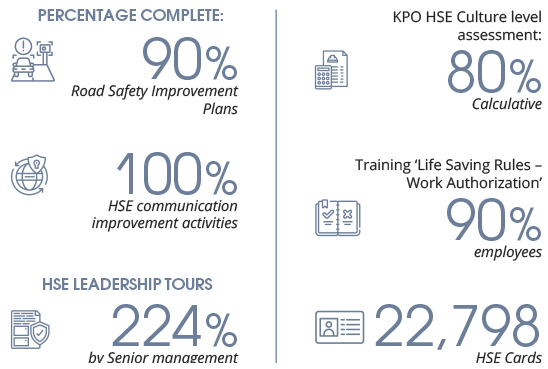

HSE improvement plan for 2022

The overall objective of KPO HSE Improvement Plan is to improve Health, Safety and Environment management, to further control risks and to prevent harm to people and the environment. This is done by implementing Key Focus Elements that are over and above KPO’s day to day business activities to deliver tangible benefits and improvements.

In 2022, KPO applied a structured approach in preparation of the HSE Improvement Plan to ensure the Plan and the KPIs support each other and HSE objectives are achieved.

Tab.14. 2022 KPO HSE Improvement Plan consisted of level I-II-III interlinked objectives:

|

LEVEL I (main goal): |

No harm, no leaks |

|

LEVEL II (supporting goals): |

|

|

LEVEL III (how this will be achieved): |

Strategy and Key Focus Elements |

- The subordinate plans were developed and implemented to address these objectives;

- All KPO stakeholders owned and shared objectives and subordinate plans;

- KPO worked together to implement the plans and strengthen the barriers, in order to achieve the common highest goal.

Monitoring of the Plan was arranged by means of Traffic Light system (Green, Yellow, Red) applied to Levels I, II and III.

In the following paragraphs, we present the activities implemented in 2022 on HSE Leadership, HSE Culture and Road Safety. Environment protection, Asset Integrity, Risk Management and Health activities are covered in relevant chapters.

HSE leadership and culture

In 2022, Corporate Safety started the implementation of the “Safety Leadership and Culture Program” – Coaching. The Programme is focused on KPO and Contractors frontline leaders involved in high-risk activities who have subordinate team to supervise and whose role is to maintain barriers to prevent or mitigate hazards on site. Before Coaching, SLCP implementation team conducted the “Coaching, Engagement and Intervention” courses for the selected candidates at units, specifically:

- 108 individual practical sessions for 14 frontline supervisors at Unit-3 and Unit-2.

- Since July 2022, 33 individual sessions for 12 contractors’ foremen of the Project Execution Directorate, coaching process will be continued in 2023.

- During the year, Train-the-Trainer sessions for KKS-Sicim, Syrlasu, KazCargoExpress, KarInfraStroy contactor companies.

Number of assessments were done to identify the level of HSE Culture in KPO: 2 KPO internal assessment by peers (in March and December) and assessments by third parties and Operators (in July-August 2022). Outcome of the KPO HSE Culture level assessment: 80 % Calculative (we have systems in place to manage all hazards). The following areas for improvement were identified:

- one team approach (KPO & Contractor),

- intervention and reporting,

- complacency,

- ownership for safety,

- communication skills,

- understanding of risks & hazards.

HSE Promotion and Awareness-Raising Tools

KPO is committed to fostering Health, Safety and Environmental culture. Thanks to the concerted efforts of all HSE departments all scheduled HSE communication improvement activities and campaigns were 100 % completed in 2022.

Quarterly HSE quiz was launched, every employee could check his or her basic HSE knowledge and win a gift. Continuous focus was made on raising awareness of employees and on prompt communication through daily pop-up messages and regular HSE moments which highlighted important issues and provided guidelines to follow. Throughout the year 19 HSE moments were issued covering different topics such as incident reporting, intervention, road safety, environmental care etc.

Two e-learning courses were developed on ‘Life Saving Rules – Work Authorization’, which was successfully passed by 3,647 employees and ‘New RoQ Eco-Code, Transition to Green KPO’, which was passed by 3,985 employees.

In July 2022, Safety Stand Down was held with all company and contractors’ employees on the theme ‘Incident Reporting’ to highlight the importance of timely reporting of all incidents. Some real cases of delays in incidents’ notifications and negative implications that followed were discussed.

There was also the Safety Stand Down with Company drivers to highlight the benefits of proper planning for trips and basic road safety rules in accordance with Life Saving Rules including wearing safety belts, use of mobile phone while driving, speed limits etc. In addition to the presentation a video was made.

Annual HSE Forum has been an effective communication tool for many years. In December 2022, KPO held HSE Forum with its contractors to discuss the “Leader’s role in creating effective culture. The Forum was attended by KPO and contractors’ senior management. The objective of the Forum was to jointly discuss current issues and seek for solutions to improve overall culture at the Karachaganak field including safety culture, driving culture, mental health and environmental consciousness of employees. The Forum included group interactive sessions, team tasks, surveys and games to allow for in-depth evaluation of the causes of deeply-rooted behavioural aspects and cultural beliefs as well as planning for improvements and prevention.

Management presence on work sites

For tracking the overall HSE performance and management interaction with employees at work sites, KPO practices HSE site tours: HSE Leadership tours engaging KPO Directors/Controllers, as well as Contractors’ senior management, and HSE Management tours for Level 2-3 Managers. The main principle of this program is interaction with the workforce.

In 2022, the total number of HSE Leadership tours amounted to 204 compared to the planned 91 having resulted in 224 % plan completion and HSE Management tours amounted to 924 compared to the planned 1013 having resulted in 91.5 % plan completion.

Road safety

To ensure more sustainable road safety performance, KPO continues implementing its annual Road Safety Improvement Plans. In 2022, KPO completed 90 % activities of the Plan.

Key road safety achievements/implemented activities in 2022:

- 0.00 RTIF by the end of 2022 (for the third year in a row);

- ISO 39001: Road Traffic Safety Management System – successful (zero non-compliance) certification;

- Driving competence assessment of more than 286 KPO and Contractors’ drivers both randomly and by applying risk-based approach, e.g. based on IVMS RAG reports, vehicle type, load type, km driven;

- Road traffic safety assurance review of 13 top low-performance contractors;

- Road Safety Stand-Down for KPO and contractors’ drivers on risks of driving in winter, including risk of hitting animals on the roads;

- Arrangement of catastrophic RTI drill with involvement of KPO Emergency Response and Health teams;

- Update of procedure for Inspection of KPO and Contractor Vehicles;

- Update of KPO Road Hazard Assessments for the main routes (new hazards, risks, control measures, new format) and upload to KPO Intranet;

Also, within the framework of cooperation on road safety improvement with the authorities and the community, KPO carried out/participated in the following activities in 2022:

- Meeting with Akimat, Road Police of Burlin region and local farmers regarding uncontrolled domestic animals was conducted. As a result, a Whatsapp group was created with participation of listed above representatives in order to settling the issue. Also, in order to provide access for local farmers to remove their wandering animals from the Field territory, KPO arranged trainings on defensive driving and H2S, issued RPE and inspected the vehicles;

- 10 domestic animals’ mannequins were installed on the public roads leading to the Field in order to prevent RTIs with animals;

- 15 children’s mannequins were handed over to Akimat, which were installed on pedestrians’ crossings (mainly near secondary schools) in Aksai;

- On 1st June, on International Children’s day, road safety awareness event was organized for children in Aksai, which included conducting various contests and memorable gifts for participants;

- At the beginning of new academic year, bags for shoes with reflective strips and main road safety rules on them were handed over to the 1st grade pupils of secondary schools in Burlin region;

- New road safety audio clips subject of “animals on the roads” and “vehicles blind spots” were issued on the Aksai Radio;

- Road safety banners were renewed in Aksai.