OPERATIONS

|

Business principle:

Economic

|

Long term profitability is essential to achieving our business goals and creating value for our shareholders and the Republic of Kazakhstan. |

|

Business principle:

Environment

|

We continually look for ways to reduce the environmental impact of our operations. |

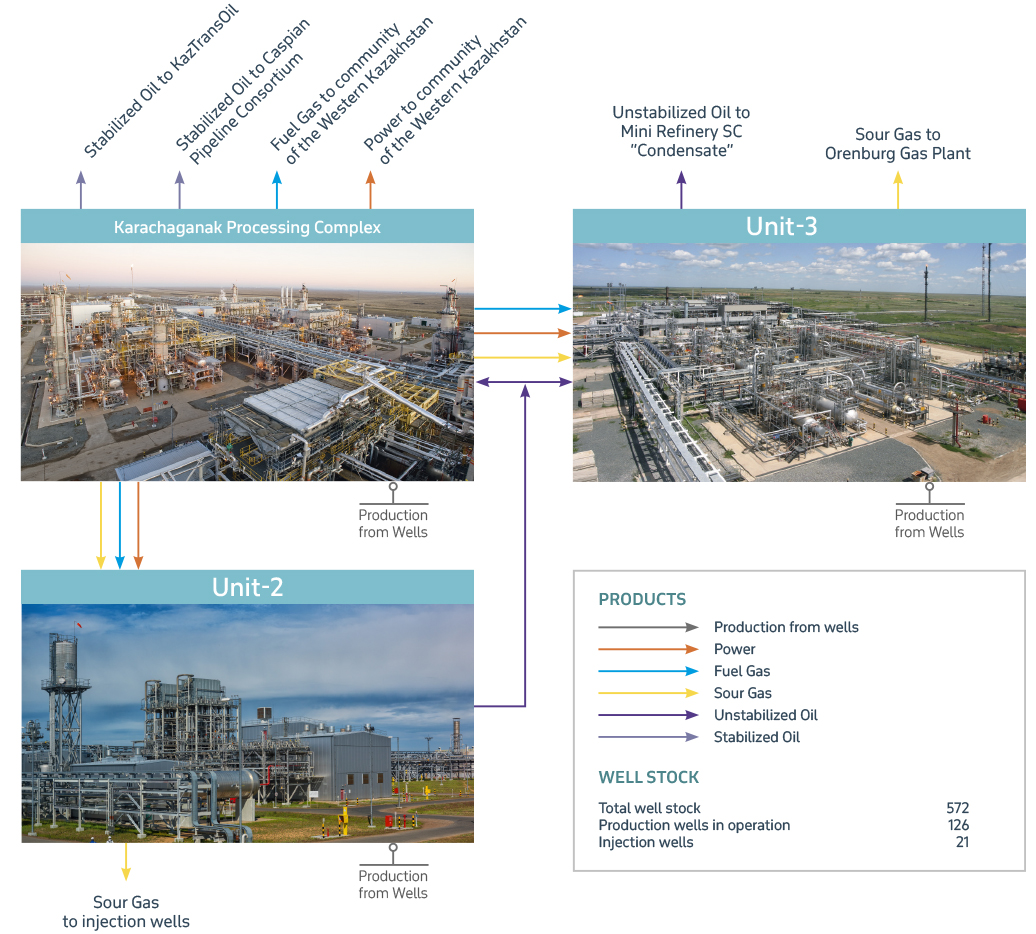

KPO FACILITIES

Hydrocarbon production and processing at KPO involve three major interconnected units: Karachaganak Processing Complex (KPC), Unit 2 and Unit 3. The infield system, comprising approximately 2,000 kilometres of pipelines, efficiently links the major facilities and facilitates production flows from the wells and among the units. Additionally, the system includes an Early Oil Production Satellite (EOPS) and Eco Centre, as illustrated in the Figure 4.

The transportation system, operated by KPO is covering two directions:

- Karachaganak – Atyrau Transportation System (KATS):

- Equipped with pumping stations at KPC and Bolshoi Chagan.

- Features a receiving and storage facility at the KPO Terminal in Atyrau.

- Karachaganak – Orenburg Transportation System (KOTS):

- Used for transporting gas to Orenburg Gas Plant in the Russian Federation.

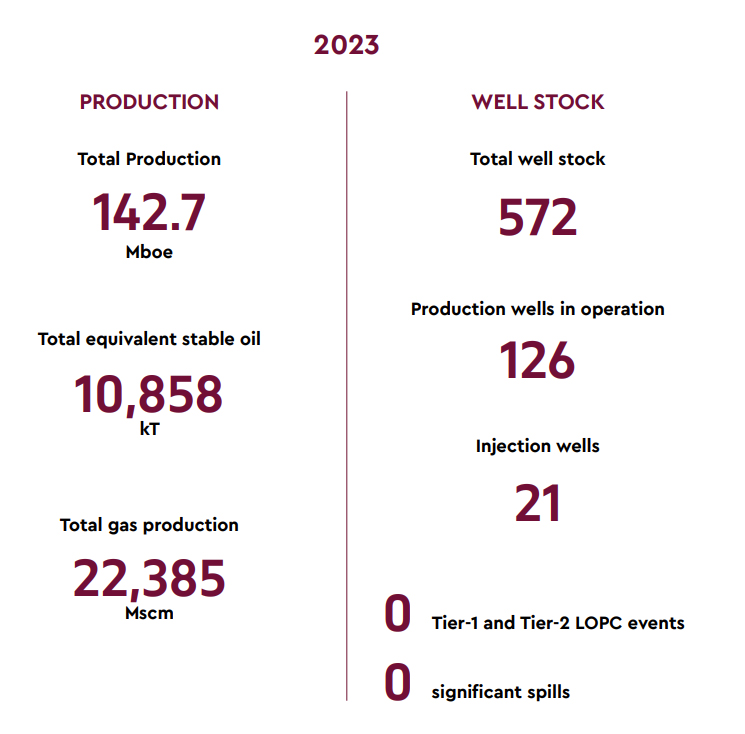

As of end 2023, 126 producing and 21 re-injection wells were online at Karachaganak, from a total well stock of 572 wells. In 2023, a new category “Surface waste and wastewater accumulation areas observation wells” consisting of 94 wells was added to the special well stock as well as one abandoned well of this category. Therefore, number of special wells was increased by 95 wells and consists of 279 wells as of 01.01.2024.

AS OF END 2023, 126 PRODUCING AND 21 RE-INJECTION WELLS WERE ONLINE AT KARACHAGANAK, FROM A TOTAL WELL STOCK OF 572 WELLS.

In the reporting period, 4 production wells and 3 gas injection wells were drilled. The drilling of two production wells was started in Q4 2023 and completed in Q1 2024. Workover activities were carried out in three wells.

Fig. 4.Karachaganak facilities and products (as of end 2023)

KPO is the Operator of the Karachaganak oil and gas condensate field (KOGCF) which is located in North-West Kazakhstan and covers an area of over 280 km2. Karachaganak is a unique field with complex operating conditions, not in the least due to extreme continental climate. The field is some 1,600 m thick and very complex and unique with its top at a depth of around 3,500 m. The extracted hydrocarbons contain up to 4.5 % of highly toxic and corrosive hydrogen sulphide (H2S), as well as carbon dioxide (CO2) which can be highly corrosive in certain conditions.

According to the latest Reserves Re-Determination Report for the Karachaganak field (accepted by the RoK State Reserves Committee (GKZ) on 17.11.2017), it is estimated that the Karachaganak Field contains some 13.6 billion barrels of liquids and 59.4 trillion cubic feet of gas, of which approximately 15.5 % of liquids and 14,5 % of gas have been recovered as of 2023.

The Company invests heavily into the application of leading-edge technologies to maximize sustainable economic value and minimise environmental impact. The total investment in the development of the Karachaganak oil & gas condensate field since the signing of the FPSA in 1997 to 31.12.2023 has totalled over USD 31.3 bln. As of end 2023, 4,080 people worked in the KPO organisation.