Water consumption and disposal

Protection and rational use of water resources is an important and priority task facing both all mankind and our company. Water is the source of life and a valuable industrial raw material.

The results of our work to minimize the risks of the Company’s production impact on the use of water resources presented below.

Water consumption

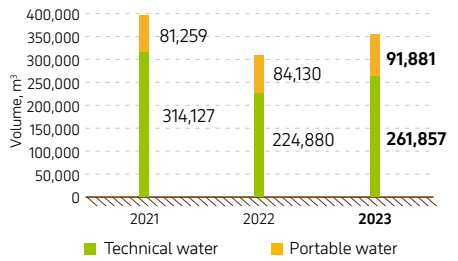

In 2023, the total water withdrawal in the Company amounted to 353,738 m3, of which 261,857 m3 was the technical water and 91,881 m3 was the potable water.

Graph 25.Water withdrawal in KPO, 2021–2023

In 2023, KPO consumed water by 15 % less compared to 2022. Domestic water consumption was slightly higher than in 2022 which was due to the increase of well operations and construction of new facilities.

In 2023, the volume of water consumed for production processes and for technical needs (not returned to ecosystem after the water intake) made up 182,419 m3.

There is no seepage flow into the Konchubai Gully. The water flow only occurs during the spring-time snow melt and rains. In 2021, the combination of prolonged dry periods and little snow floods observed in the region has led to a critical decrease in the water level in the Reservoir № 1. In this view, in the past last two years, KPO has been carrying out a number of activities allowing optimization of technical water consumption and increase the reuse of treated wastewater, rainwater, and melt water. Besides, after conducting experimental filtration studies at wells, groundwater from wells was sent to operational facilities for reusing for technical needs.

From January 2022 to March 2023, in order to avoid damage to the reservoir, there no water intake for technical purposes was made from Konchubai Gally.

During the spring snowmelting in 2023, the water level at the Konchubai Gully raised up, which allowed to cover the technical water needs of production at the KPO facilities.

KPO Water supply sources

Prior to 2023, the main source of water supply for KPO production needs was a reservoir No.1 at Konchubai Gully. For the domestic needs, KPO used water from the Zharsuat water intake. Sources of water supply for domestic and process needs at the pumping station in Bolshoy Chagan is the Serebryakovskiy water intake, while the Atyrau pumping station is supplied from the Kigach water intake.

The Karachaganak Oil Gas Condensate Field is based in area with no water shortage according to Atueduct Water Risk Atlas source of Water Resources Institute https://www.wri.org.

Also, the sources of water supply are the ground water from Akchagyl underground reservoir, wells No. W-4, W-9 inside the Feild as per the Permission for Special Water Use issued by the Zhaiyk-Caspian Basin Inspectorate under No. KZ92VTE00093596 Series Kas. Zhaiyk (groundwater) dated 02.08.2022 and water of technical quality from Reservoir No. 2 on Konchubai Gully under the contracts with Industrial Construction Services KAZ LLP. Water withdrawal from other water intakes is conducted on the bases of contracts with water suppliers.

Technical water is used from Reservoir No.1 of the Konchubay Gully, under the Special Water Use Permit issued by the Zhaiyk-Caspian Basin Inspectorate № KZ43VTE00079540 Series Kas. Zhayik (surface) dated 19.10.2021 (valid till 24.05.2025).

Treated domestic, rainwater, and melt wastewater is reused for technical purposes, if the quality is in compliance.

In 2023, the potable water was used for domestic needs of KPO facilities. By exception, due to the lack of alternative water sources, the potable water on Bolshoi Chagan’s Pumping Station is used for technical purposes to refill fire water tanks and ensure the fire safety.

On potable water usage for the Karachaganak Field facilities, KPO is the secondary user under contract with AksaiGasPromEnergo LLP, a supplier of potable water from Zharsuat water intake.

Table 38 shows KPO water consumption breakdown by source.

Tab. 38.KPO water consumption in 2021–2023 by sources, m3

|

# |

Source |

Facility |

Water quality |

2023 |

2022 |

2021 |

|

1 |

Zharsuat water intake facility (household needs) |

Karachaganak field (KOGCF) |

groundwater, potable |

90,257 |

82,404 |

79,852 |

|

2 |

Konchubay Gully, Reservoir 1 |

Karachaganak field (KOGCF) |

surface water, technical |

206,140 |

14,130 |

310,352 |

|

3 |

Ground waters from Akchagyl underground reservoir, Wells W-4, W-9 |

Karachaganak field (KOGCF) |

ground water, technical |

– |

4,967 |

– |

|

4 |

Technical quality water from Reservoir 2 |

|

surface water, technical |

50,920 |

172,450 |

– |

|

5 |

Reuse for process needs of rain water and produced water from wells after well testing |

Karachaganak field |

re-use |

10,445 |

30,816 |

– |

|

6 |

Serebryakovskiy water intake facility |

Bolshoi Chagan OPS |

groundwater, potable |

1,624 |

1,726 |

1,407 |

|

|

for household needs |

|

|

645 |

670 |

868 |

|

|

for production needs |

|

|

979 |

1,056 |

539 |

|

7 |

Kigach water intake facility |

Atyrau OPS |

surface water, technical |

4,797 |

2,517 |

3,775 |

|

|

for household needs |

|

|

776 |

749 |

808 |

|

|

for production needs |

|

|

4,021 |

1,768 |

2,967 |

Note: water consumption is metered using meters with measurements recorded in the logbooks and further in the KPO water consumption metering database.

Treated wastewater discharges

KPO uses special man-made facilities for collecting treated domestic and industrial wastewater and storm runoffs. These facilities exclude an option of contaminants’ soaking into the soil and groundwater and allow collecting the treated wastewater for their reuse for technical needs, thereby reducing the fresh water intake. Wastewater collection facilities by type are presented in table 39.

Tab. 39.KPO wastewater collection facilities by types

|

Type of wastewater |

Treated domestic wastewater |

Industrial wastewater and storm runoffs |

Rainfall and snow melt wastewater |

|

Facility and location |

|

|

|

Formation water produced with hydrocarbons and process wastewater are treated and injected into the deep-lying formations of the Karachaganak Field Subsurface Wastewater Disposal Polygons 1 and 2. Wastewater injection is the international practice of disposing wastewater, avoiding the formation of salt-containing waste on the surface during the treatment. Due to the reliable water shutoff and soil properties, which are ideal for the injection of wastewater, the migration of wastewater into upper aquifers is ruled out.

In 2019, the Company has developed the Unified concept of options for the treatment of wastewater injected into the underground strata, alternative to the strip column at Unit-3. Two alternative options were suggested for consideration as most appropriate solution:

- Disposal of wastewater from Unit-3 to Unit-2 using the Unit-2 production water treatment system (the existing H2S strip column);

- Disposal of wastewater from Unit-3 to the existing 14” condensate pipeline to KPC.

Due to optimization of resources and maintaining compliance with the RoK requirements, the Company stopped project development on strip column installation at Unit-3 and from 2020 has continued development of the design project on the second alternative option of the wastewater treatment at Unit-3 as defined by the Unified Concept Report.

In 2020, the project “Unit 3. Process Water Line Jump-Over of the KOGCF” was implemented, the aim of the project was to reduce the H2S concentration in the injected wastewater by re-routing process water from Unit-3 to KPC via the existing condensate pipelines. The project includes installation of a jump-over line to reroute produced water from Unit-3, which is currently supplied to Polygon 1 RP-1 and RP-3 wells, to KPC via the existing condensate pipelines transporting unstable condensate from Unit-2 and Unit-3. Water will be separated and further supplied to the KPC existing produced wastewater system.

According to the RoK legislation, the volume of discharged wastewater and number of discharged contaminants are estimated and justified in the Company project documentation and regulated by special permits. Wastewater generated as a result of the KPO economic and production activities is not discharged into the natural water bodies.

In the production process of hydrocarbons, the separated formation water is pumped down to the underground water horizons (polygons). In 2023, this volume has made up 669,443,4 м3. This water volume includes the formation water, the water formed during the gas dewatering and the water after the caustic neutralization. Water taken from the Konchubai Gully for desalting of crude oil and for the the reverse osmosis is also injected into the polygons. In 2023, this water was 17,23 % of the total water injection.

Table 40 shows the KPO discharge volumes in 2021–2023 by wastewater types and receiving facilities.

Tab. 40.Total discharge volume and contaminants by wastewater type and receiving facility, 2021–2023, m3

|

Receiving facility |

Type of wastewater |

2023 |

2022 |

2021 |

|||

|

Discharge volumes, m3 |

Amount of contaminants, tonnes |

Discharge volumes, m3 |

Amount of contaminants, tonnes |

Discharge volumes, m3 |

Amount of contaminants, tonnes |

||

|

Holding ponds |

Treated domestic wastewater |

27,484 |

15.20 |

42,412 |

29.44 |

72,123 |

44.51 |

|

Subsurface Wastewater Disposal Polygons |

Industrial and storm wastewater, process and formation wastewater |

808,777 |

68,26 |

764,139 |

60,699 |

780,755 |

58,935 |

|

Terrain of Bolshoi Chagan OPS and Atyrau Terminal OPS |

Rainfall and snow melt wastewater |

4,501 |

2.33 |

3,168 |

1.81 |

2,538 |

1.595 |

|

Total discharge |

840,762 |

68,843 |

809,719 |

60,730 |

855,416 |

58,981 |

|

Note: the volume of water discharge is metered, meters data entered in the logbooks and further in the KPO water consumption metering database. The amount of contaminants discharged is defined by calculation as the product of the actual concentration of the contaminant before the discharge and the actual volume discharged.

In 2023, the volume of discharged wastewater increased by 3.3 % as compared to 2022. Of which, in 2023, the volume of injected industrial wastewater increased by 5.1 % as compared to 2022. The increase in industrial wastewater in 2023 was due to the produced water growth in the hydrocarbons production. The volume of discharged treated domestic wastewater decreased by 35.2 % as compared to 2022 due to suspension of treated domestic wastewater discharge from the bio ponds of Trains A and B to the KCC holding ponds 1 and 2 to accumulate water for technical reasons.

In 2023, the discharge of contaminants amounted to 68,843 tonnes (which was 11.8 % more compared to 2022 – 60,730 tonnes). Only 0.1 tonnes were discharged over the limit. Insignificant excess volume of discharged pollutants was reported for associated wastewater, injected to subsurface horizons of the Polygon № 1, namely the exceedance was on petroleum products.

KPO controls the content of pollutants in wastewater. According to the Project of Regulatory Permissible Discharges for 2023, the composition of pollutants in discharges includes the following: suspended substances, ammonium nitrogen, nitrates, nitrites, BOD 20, BOD 5, petroleum products, sulfates, chlorides, iron, anionic surfactants, phosphates, COD, dry residue, pH value, sulfides, hydrogen sulfide, methanol, copper, zinc, aluminum.

The Company made necessary payments for the generated contaminants discharges in 2023.

In general, wastewater injection has no effect on the environmental components such as soil, flora and fauna, as wastewater is injected into effectively isolated deep horizons with high-mineralized groundwater that is not used for domestic and potable, balneological, process needs, irrigation and farming.

Reuse of treated and other wastewater

In order to reduce the intake of natural technical water, KPO uses treated domestic, industrial and rainwater and storm wastewater for the technical needs of the Karachaganak Field, for such types of activities as drilling, preparation of drilling fluids, irrigation of forest plantations, dust suppression on roads and construction sites, and filling fire water tanks.

The wastewater is re-used at the Company facilities in line with the 2023–2028 Operating Procedure.

In 2023, the Company reused 56,467 m3 of treated wastewater for technical needs, mostly to make drilling mud. Table 41 shows the activities that utilize treated wastewater and water.

Tab. 41.Reuse of treated wastewater and groundwater in 2021–2023, m3

|

|

2023 |

2022 |

2021 |

|

The total volume of re-used treated wastewater, including: |

56,467 |

75,452 |

35,061 |

|

Technical needs of the operational facilities |

13,383 |

42,161 |

3,362 |

|

For drilling and drilling mud preparation |

26,095 |

18,509 |

5,317 |

|

Irrigation, hydro tests, and replenishing of fire tanks |

1,996 |

10,376 |

8,465 |

|

Dust suppression and watering |

14,993 |

4,406 |

17,917 |

Note: the volume of reused water is measured indirectly in m3 (motor hours, tank truck volume, number of trips, pumping capacity, etc.) with the completion of a control ticket and data entered in the logbook

Industrial wastewater management

Tab. 42.Targets in managing effluents

|

Our 2023 targets |

Target achievement status |

Actions taken in 2023 |

Targets for 2024 |

|

Carry out workover on the injection well RP-6 in order to increase the perforation intervals in the Triassic Reservoir II. |

Completed |

Workover of RP-6 well of the Triassic Reservoir II+III has been carried out from 12.10.23 till 05.11.23. |

Carry out workover on injection well RP-7 in order to increase perforation intervals in the Triassic Reservoir. |

|

Completed |

|

|

Managing the formation water and industrial effluent water is one of the main challenges faced by KPO in the Karachaganak Field.

KPO’s industrial water management strategy consists of implementation of a portfolio of interconnected projects aimed at removal of production restrictions in terms of formation water handling as well as ensuring personnel safety, asset integrity and environmental compliance.

As mentioned in the report for 2022, in 2022, Addendum No. 3 to the current industrial Wastewater Disposal Project was developed in terms of adjusting design parameters and a report on possible impacts was drawn up. These documents were agreed by the Department of the Industrial Safety Committee and received a positive conclusion from the Committee for Environmental Regulation and Control.

Addendum No. 3 to the Wastewater Injection Project reflects an increase in wastewater injection volume from 2023 until the end of FPSA in 2037 up to 1,100 thousand m3 per year, as well as the implementation of technical measures to increase the potential of the injection well stock through additional perforation of target and prospective injection intervals and hydraulic fracturing.

In accordance with the requirements of the Environmental Code of the Republic of Kazakhstan and the Rules for Conducting Post-project Analysis on “Amendment No. 3 to the project for the injection of industrial wastewater into deep-seated aquifers in terms of adjusting design indicators and the EIA section” in January 2024, the project plans include carrying out a post-project analysis of design solutions and develop a conclusion with further posting at the portal of the Environmental Regulation and Control Committee to the RoK Ministry of Environment and Natural Resources.

The project of upgrade of a caustic neutralisation unit was ongoing since 2022; the start-up is expected in 2024.

As part of the implementation of the Design project decisions and in order to increase the perforation intervals in the Reservoir II, the workover of the well RP-6 was carried out in 2023. According to the KOGCF Wastewater Design project the similar workover in the RP-7 well is planned in 2024.

To support the plan to increase the scope of injected water in the Polygon 2, the Project of upgrade of sand and guard filters is currently ongoing with anticipated start-up in 2024.

Tab. 43.Industrial wastewater management projects, ongoing in 2023

|

Project |

Business driver |

Note |

|

Upgrade of a caustic neutralisation unit |

Safe operations |

Implementation of the project will provide improvement of the caustic neutralization process (CNU). By means of process automation the risks for personnel exposure to toxic agents will be reduced. Importantly, the upgraded CNU project will be able to partly utilize the Reverse Osmosis water that otherwise would have been disposed. |

|

Upgrade of sand and guard filters |

Production maintenance |

Upgrade of sand and guard filters will allow to achieve KPC water treatment capacity to 115 m3/d. |

|

Technical Water Supply from the Aksai Wastewater Treatment Plant |

Production maintenance |

A Feasibility Study has been conducted by KPO to synergise with a Project of the Upgrade of Aksai Wastewater Treatment Plant currently ongoing with the Akimat. Concept has been developed and the project progresses further. |

Ensuring access to safe water and sanitation is a human right.

Excessive and irrational water consumption can lead to impacts associated with the depletion of water resources and water shortage for industrial and economic needs, deterioration of aquatic ecosystems and decrease in the ability of water resources to naturally reproduce and purify.

The Company’s target is to use water resources rationally with the aim to preserve them. KPO controls the use of clean water by undertaking a set of measures on conservation of water resources and re-use of treated water, wherever possible.