Sustainability

- Home

- /

- Sustainability

- /

- Asset Integrity

Asset Integrity

The main objective of Asset Integrity is to prevent major accidents and reduce the risks to people, environment, assets, and the Company’s reputation. It is an outcome of good design, construction, operating and maintenance practice.

Asset Integrity is achieved when facilities are structurally and mechanically sound and perform the processes to produce the products for which they were designed. Barriers that relate to the plants, people and processes are defined to reduce the risk for a major accident to a level that is as low as reasonably practicable.

KPO monitors potential threats to its operations and mitigates Asset Integrity risks through its barrier management system. In order to reduce the risk, we have defined barriers that relate to plant, people and processes, thus managing the major accident hazards to a level that is as low as reasonably practicable. The Asset Integrity department together with the Units continuously assess the health status of the safety barriers to identify weaknesses, implement mitigating measures and establish plans to re-instate these barriers to its original design to prevent any major accident.

Loss of Primary Containment (LOPC) is an unplanned or uncontrolled release of any material from primary containment, including non-toxic and non-flammable materials. The Annual Loss of Primary Containment Report for 2021 provides an analysis of the LOPC incidents that occurred during 2021 along with their defined recovery actions in terms of:

- Root causes (in accordance with Incident Investigation Tap Root Methodology),

- Level of compliance with Process Safety Fundamental rules,

- Status of corrective actions,

- Weeps & Seeps Leaks Register data.

Analysis of Process Safety Events is the key to prevent or reduce the likelihood and severity of Process Safety Events. Once a Process Safety event occurs, an investigation process is initiated, root causes are determined and recommendations are defined and followed up through the Synergi database.

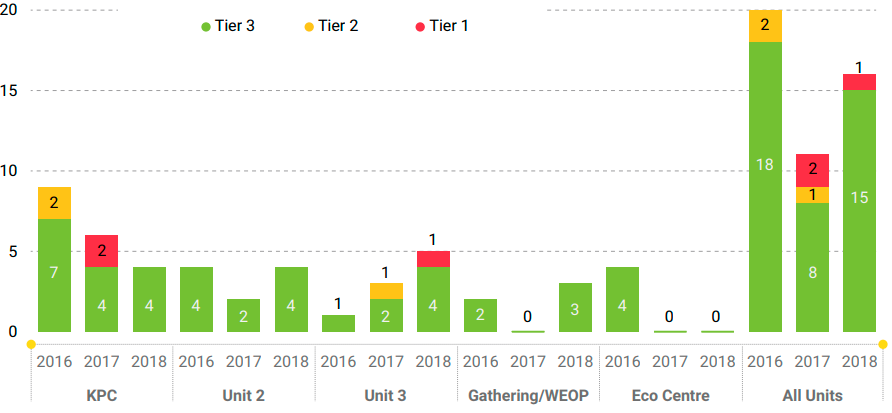

Statistical analysis for 2019-2021 shows that the number of LOPC events decreased by 44.4% in 2021 compared to 2020. One Tier 1 Process Safety event occurred at KPC where a release of caustic soda solution splashed into the face of a KPO Lead Operator during the pressure leak testing activity. The injured person immediately used an eyewash in the safety shower and received first aid and further medical examinations; his eyesight was not impacted, however the sick list was issued. No Tier 2 LOPC’s occurred in 2021. The number of Tier3 LOPC’s was reduced from 17 in 2020 to 7 in 2021.

Loss of Primary Containment at KPO by process facilities, 2019-2021

Note: For Process Safety Event definition (Tier-1/2/3), please refer to the International Standard IOGP 456.